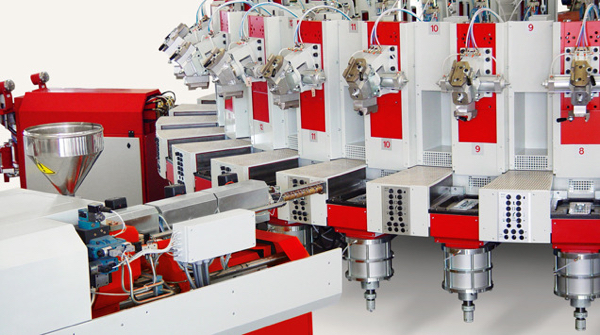

For over 20 years committed to developing technologies and manufacturing machines for the production of articles in polyurethane, Stemma renews its range of machines for the direct injection of uppers of shoes in polyurethane by launching two new proposals: Maxima 16 and Formula DM.

Maxima 16 represents the fourth series of the bestselling model of this Venetian company. Renewed by a sophisticated system of electronic control capable of guaranteeing an extremely high performance level with work cycles cut down to a minimum and maximum productive flexibility, it allows for an especially evolved interaction between man and machine, thanks to control systems and feedback specifically designed to allow for the efficient use of the machine also by non-expert operators.

Maxima 16 represents the fourth series of the bestselling model of this Venetian company. Renewed by a sophisticated system of electronic control capable of guaranteeing an extremely high performance level with work cycles cut down to a minimum and maximum productive flexibility, it allows for an especially evolved interaction between man and machine, thanks to control systems and feedback specifically designed to allow for the efficient use of the machine also by non-expert operators.

Formula DM, with a Double-Rings system, is a Stemma patented technology, which, in addition to a traditional PU/PU moulding system, allows for the production of shoes with rubber/TPU soles inserted in the mould and a dual layer polyurethane midsole in different densities/colours. Up until today, this kind of footwear was made using methods that required subsequent and/or complex steps in production. Now, instead, it can be produced during the normal productive cycle of the direct injection machine, without an increase in manpower hours or reduction in work cycles. The product is meeting up with significant interest in the outdoor sector and in the sector dedicated to military use.

Stemma machines are fully compliant with Industry 4.0 requirements, the programme promoted by the Italian government in support of development and innovation.